The Rack and Pinion Sliders Synchronizing System

We have adopted R.a.P.s. in our all counter flow rolling machine series. Because of our continuous effort and innovation, it is possible for us to get longer durability and high process accuracy.

It is important to sychronize left and right sliders/dies for precise accuracy.

In our rolling machine series we have adopted “2 Rack gears and 1 pinion gear” since we developped the machine. (See note 1)

Advantages of R.a.P.s

- Stable repeatability and accuracy.

- Less distortion and less thermal expansion and degradation after continuous processing.

- High reproducibility to home position on both ways (forward and backward).

- Easy maintenance/ adjustment.

- The structure of R.a.P.s. can avoid direct process load. Therefore, it can maintain stable accuracy in high process load and high speed processing.

- The difference of drive system such as a hydraulic motor and a servomotor

Slide’s finish process

We add hand scraping on slides to meet high accuracy, high rigidity, long service life, and high productivity. Because of the below “Advantages of scraping” we can get high reliability on our machines. (See note 2)

- Advantages of hand scraping

- Improving accuracy on slide surface

- Enhancing more smooth movement

- Improving lubrication on slide surface

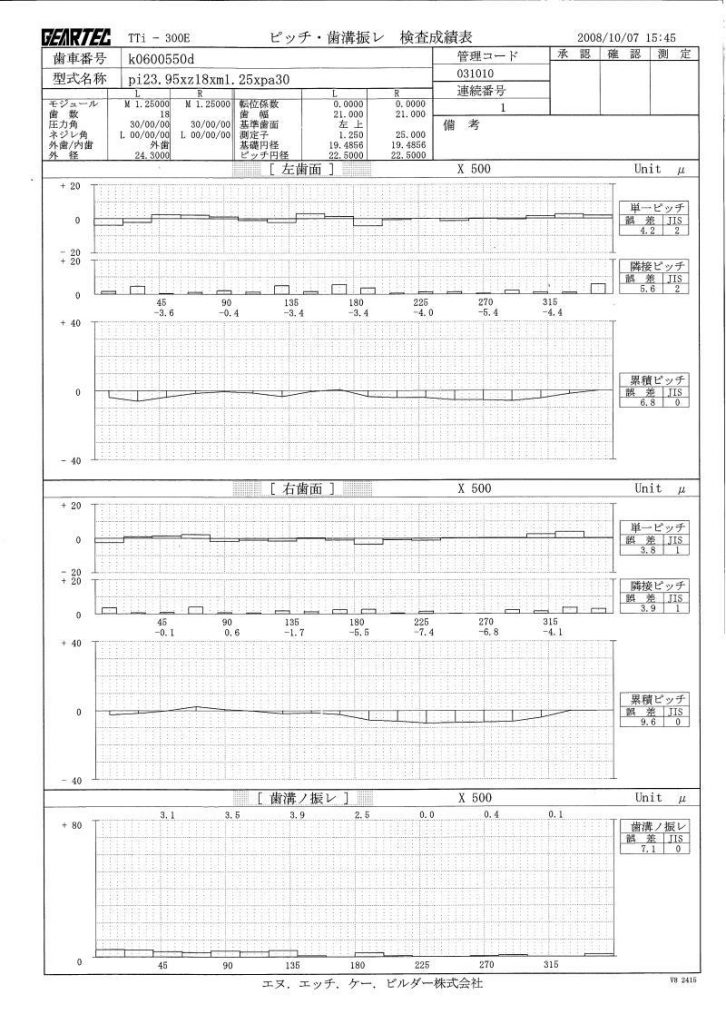

Sample of process accuracy

Pith diameter =φ23.95, No. of gear teeth =18, Module =1.25、PA=30°

*Process condition

Machine type: CT-600 (Hydraulic motor type)

Parts: Drive shaft both ends spline/ two ways rolling

Parts’s material: 40Cr

Process speed: 20m/min.

Clamp: NC + Air pressure

Coolant: Oil-based

**Measuring method

Gauge: CNC Gear gauge TTi-300E (Tokyo Technical Instruments Inc.)

Note) The above data is one of the examples. It doesn’t mean figures stand for process garantee.